Outsourcing vs. In-house Supply Chain: Pros and Cons

In the realm of supply chain management, businesses often face the critical decision of whether to outsource their supply chain needs or manage them in-house. Outsourcing involves delegating supply chain functions to external service providers. This option generally allows firms to tap into specialized expertise, enabling them to focus on core activities. Organizations can benefit from reduced operational costs, improved scalability, and access to advanced technologies. On the other hand, maintaining an in-house supply chain offers enhanced control, better alignment with business strategies, and improved communication between departments. Companies can customize their supply chain processes to align directly with their objectives. However, the costs of hiring and training personnel can be high. Companies must carefully evaluate these trade-offs, considering their industry demands, financial situation, and company culture. The right choice often hinges on weighing the pros and cons of both strategies, assessing long-term impacts, and aligning with overall growth objectives. Business leaders must analyze their specific circumstances, operational capabilities, and risk tolerance before making a well-informed decision that would drive further efficiency and effectiveness.

Benefits of Outsourcing Supply Chain Management

Outsourcing supply chain management offers numerous advantages that businesses find appealing. Firstly, by working with specialized third-party providers, companies gain access to advanced technology and expertise not always available internally. This access can lead to enhanced efficiency and innovation. Additionally, outsourcing allows businesses to reduce operational costs significantly, as external providers often have greater bargaining power with suppliers. Companies can convert fixed costs into variable costs, resulting not only in cost savings but also providing flexibility to scale operations depending on market demand. Furthermore, outsourcing enables firms to concentrate on their core competencies and strategic initiatives, while letting experts manage the logistics complexities. It can also foster greater focus on customer satisfaction since specialized providers often excel in service delivery. However, despite the advantages, companies must remain cautious about potential risks. Loss of control over the supply chain processes might lead to challenges regarding quality and service standards. Hence, enterprises should conduct thorough due diligence to choose a reliable outsourcing partner, balancing cost benefits against potential risks to ensure the desired outcomes if they decide to outsource.

In-house supply chain management can provide a plethora of benefits that suit certain organizational needs. For many businesses, managing their supply chain internally allows for more control over operations, providing the ability to implement rapid changes or adjustments without relying on external providers. Furthermore, having a dedicated supply chain team fosters a sense of organizational alignment, as these professionals often become experts on the company’s specific products and processes. In-house teams can focus on building strong relationships with suppliers, ensuring quality and consistency across the supply chain while aligning closely with other departments such as marketing or R&D. An internal supply chain also permits smoother communication during product development cycles, allowing firms to react quickly to market changes or customer demands. However, managing a supply chain internally can incur high overhead costs and may lead to resource limitations if expertise is not available. Another consideration is scalability; as demand fluctuates, in-house operations may struggle to adapt without substantial restructuring. Consequently, businesses must assess their capabilities and how their choice aligns with broader strategic objectives when considering an in-house solution for supply chain management.

Challenges of Outsourcing Supply Chain Functions

Despite the advantages of outsourcing supply chain functions, there are inherent challenges that organizations must navigate. Primarily, losing direct control over outsourcing partners poses a significant risk. Firms often find it challenging to maintain oversight and quality standards across distances. This can lead to issues with product quality, delayed shipments, and unsatisfactory customer service, as the outsourced entity may have different operational standards than the parent company. Additionally, the reliance on a third-party provider can result in vulnerabilities, especially if the vendor underperforms or fails to meet expectations. Companies could face disruptions in their supply chain, leading to potential loss of revenue or market reputation. Another challenge is communication barriers that arise when coordinating across different cultures and time zones between partners and clients. This misalignment can hinder performance and strategy execution. Moreover, the strategic fit with the outsourcing partner is vital, as misalignment can lead to partnership failures. Organizations must conduct comprehensive risk assessments before outsourcing to understand these challenges and implement effective management strategies that can mitigate risks associated with reliance on third-party providers.

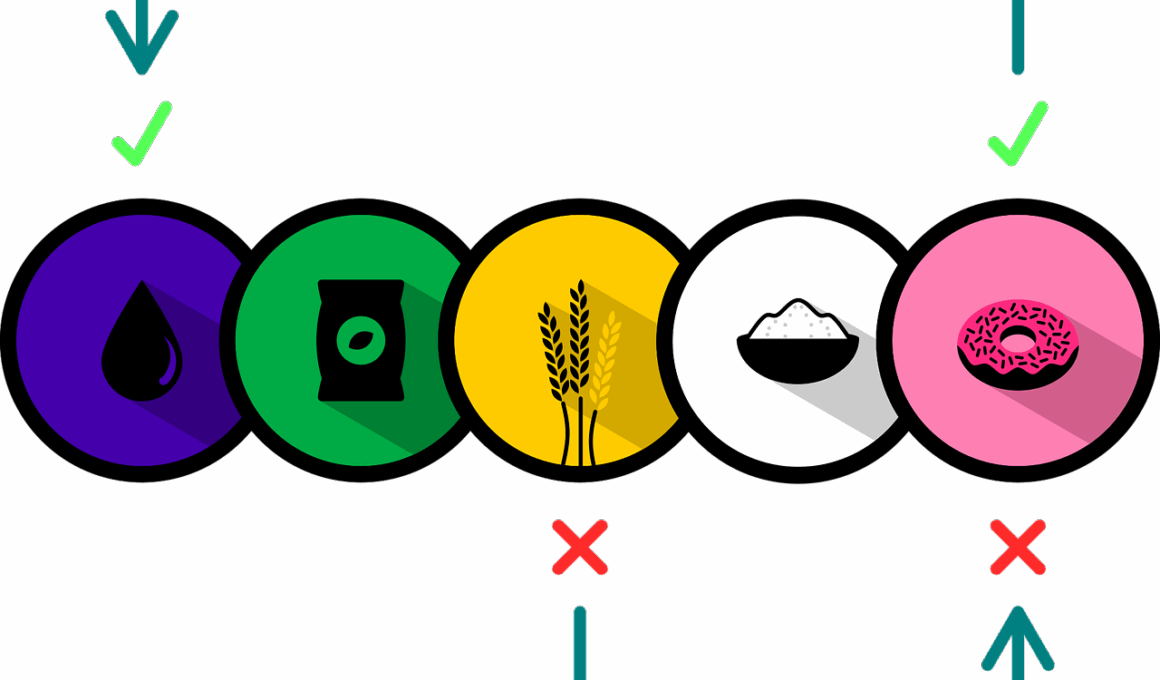

Evaluating the total cost of ownership is essential for businesses as they weigh outsourcing versus in-house supply chain management. While outsourcing can reduce upfront operational costs, organizations must consider additional long-term expenses such as vendor management, potential penalties for poor service, and hidden costs that may arise. For in-house management, businesses may need to consider hiring costs, training expenses, and investments in technology to ensure that internal teams are adequately equipped to perform effectively. Moreover, a cost analysis should take into account both fixed and variable costs across various areas of the supply chain. Companies should also conduct a comparative evaluation between the expected returns from outsourcing versus investing in in-house capabilities. It can be prudent for businesses to develop a detailed financial model that examines all relevant cost considerations. An effective analysis will help them to foresee potential challenges while establishing appropriate benchmarks. Furthermore, this financial insight will guide executives in making sound decisions relating to operational strategy, ensuring that every dollar spent contributes to enhancing efficiency and service delivery within their respective industry. Each organization must take a tailored approach to determine the financially viable path forward.

Future Trends in Supply Chain Management

The future of supply chain management is set to be influenced by a host of innovative trends that will shape its trajectory significantly. Technologies such as artificial intelligence, machine learning, and blockchain are revolutionizing how supply chains operate. These technologies enable enhanced data analytics, improving forecasting accuracy and operational efficiency. Companies are increasingly utilizing data-driven insights to make real-time decisions, minimizing disruptions caused by unforeseen events. Moreover, sustainability is becoming a prominent factor. More organizations are incorporating sustainability practices into their supply chains, which encompasses considerations for ethical sourcing, waste management, and overall environmental impact. This shift not only addresses social responsibilities but also enhances brand reputation and customer loyalty. Additionally, the COVID-19 pandemic highlighted the importance of agility and resilience within supply chains; thus, businesses are reassessing their supply chain strategies to ensure they are robust and adaptable. Furthermore, the rise of e-commerce has accelerated the need for efficient last-mile delivery solutions, pushing organizations to innovate their logistics processes. Keeping an eye on these trends will be vital for companies as they aim to maintain competitive advantages in an evolving market.

In conclusion, the choice between outsourcing and in-house supply chain management involves a complex set of considerations that every organization must evaluate carefully. These decisions can significantly impact operational efficiency, cost management, and ultimately, customer satisfaction. Outsourcing may provide cost advantages and access to advanced technology, while in-house solutions offer better control and alignment with business goals. Understanding the unique dynamics of one’s industry, market conditions, and organizational capabilities will help guide this crucial decision. Furthermore, as market conditions grow increasingly volatile, businesses should remain flexible and responsive, regularly revisiting their supply chain strategies. Many organizations may find that a hybrid approach combining elements of both outsourcing and internal operations allows for balanced risk management and operational effectiveness. As supply chain management continues to evolve, it is vital to stay informed about emerging trends and technologies that could improve processes. Implementing the best practices tailored to their specific needs will ensure that the supply chain remains a competitive differentiator in today’s fast-paced business environment. Careful analysis will lead organizations to the optimal supply chain structure that best supports their objectives and innovation in the future.